The Heath kit GC-1000 Most Accurate clock (well,

mostly anyway)

Power supply reliability upgrade information. Here's how

to do it, and it's pretty easy too!

The Heathkit GC-1000 clock was the first consumer-grade digital clock

offering disciplined accuracy performance by means of radio reception.

We have one of these venerable old WWV clocks, and being 20+ years

old it was in need of some work to restore the clock to good operation.

I'm an EE, and I also dabble in designing and manufacturing GPS disciplined

Nixie Tube clocks as a side line hobby. Hoping to shortcut the time

spend under the cover of This Old Clock, I did a search on the internet

for published information about GC-1000 failures and common problems.

I came upon a couple of internet based businesses offering repairs and

upgrades for this clock, as well as a great article about accuracy

improvement.

Our clock really was not in need of a new

CPU board, or expensive tuneup work.

I already knew the problems were related to the power supply, even

though I could not find anything published about it. I did find that

the GC-1000 is certainly a beloved item from back in the glory days of

Heathkit Inc.

OK, I had some spare time, and it was time to have a look at the clock.

It certainly was dusty inside after opening it up for the first time in

20 years.

The clock always ran hot. And heat kills electrolytic capacitors. I

looked over the power supply section with a meter and scope. Really nasty

ripple.

Twenty years running in that heat had dried out the capacitors. Plus,

the ripple was very bad for that vintage CPU, and there's no cheap replacement.

In 1983, there were few choices for voltage regulation, and none of

them very efficient. Note the discoloring of the FR4 PCB material

in the power

supply section -too much heat for too long. I decided to replace the

vintage 7805 series regulator with an Integrated Switching Regulator module,

as well

as replace many of the electrolytic capacitors within the power supply

section. The new regulator would dramatically reduce the heat generated

from the

transformer and other related components in the power supply through

improved efficiency , as well as lower the overall power consumed by the

clock.

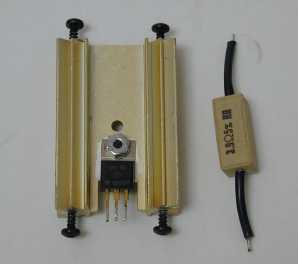

The voltage regulator U202 and it's heatsink were removed, and replaced

with a Power Trends (TI) PT5101 5V 1A Integrated Switching regulator.

I had to remove the test board that was originally mounted on top of

the regulator heat sink, and remount it with a stand off spacing it from

the board.

This PT5101N is currently available from DigiKey

for $12.25ea. The part shown on my example images will be different from

the part you receive.

Three 1000uf 25v radial Electrolytic capacitors on the main board required

replacement at locations C203, C205, and C206. One 330uf

25v radial

Electrolytic capacitor on the main board required replacement

at location C208. One 22uf 25v radial Electrolytic

capacitor at location C212 on the

main board (adjacent to the new regulator) required replacement,

and was upgraded to a 33uf 25v radial Tantalum capacitor for improved reliability.

A 3.9 ohm 5w resistor at location R201 was removed, and replaced by

an insulated jumper wire. Originally this was required to limit the incoming

voltage to the 7805 regulator, and is an unnecessary heat generator

with the new switching regulator installed in place of the vintage series

regulator.

Few other capacitors are involved with regulation, and I decided they

did not require replacement.

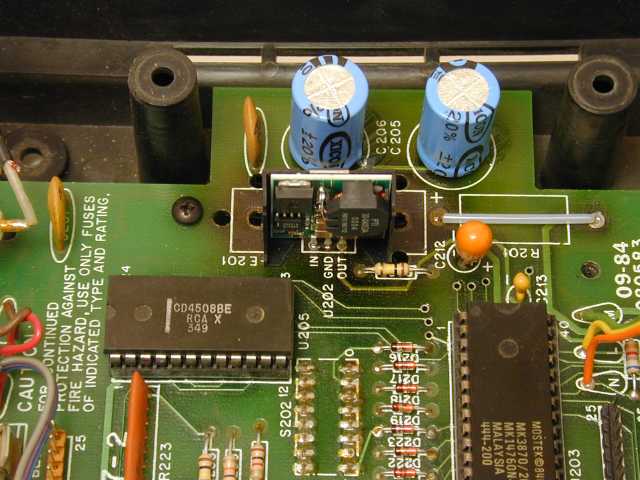

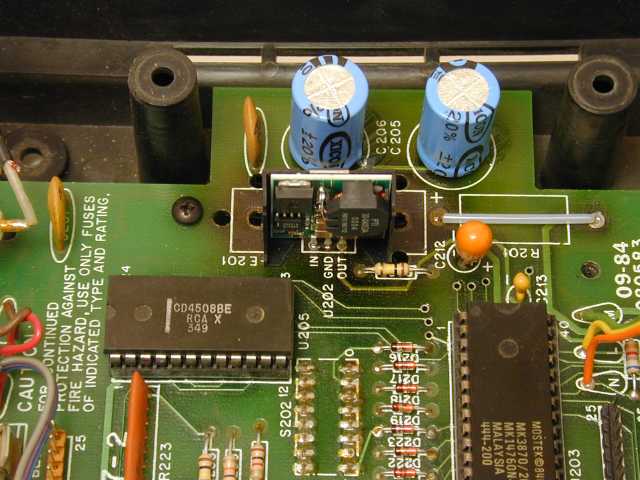

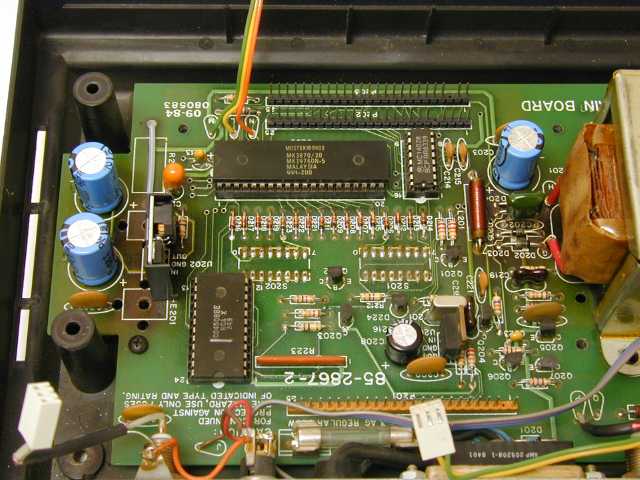

Image showing C205, C206, C212 and the new Integrated Switching Regulator

module already installed on the board.

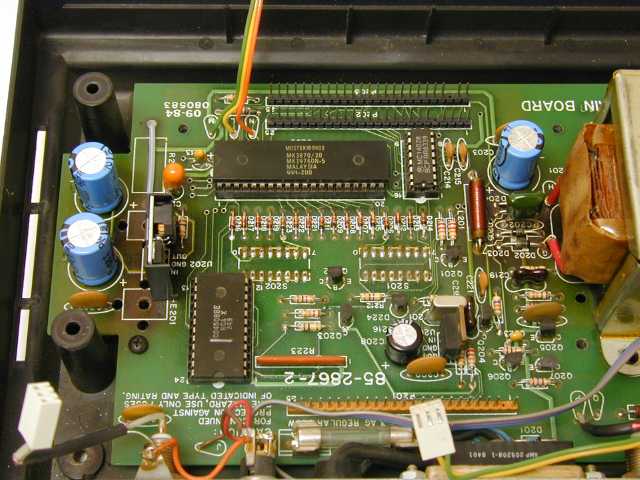

Image showing C203, C205, C206, C208, and C212. Note the toasty

FR4 board material at the voltage regulator and rectifier areas.

Image showing the GC-1000 reassembled, with a spacer installed to support

the test board over the new regulator module.

You will immediately discover the GC-1000 is operating cool, with barely

any detectable warmth from the clock cover.

I highly recommend completing the calibration procedure in the manual

after you have completed the power supply upgrade.

Update: April 2005

I recently noticed the fellow who offers the expensive GC-1000 tuneup

work has added a "cool clock" blurb to his web site.

Apparently this new blurb is in response to my posting of the GC-1000

information -enabling you to perform the PS reliability

upgrade work yourself at little or no cost. Don't be misled into purchasing

an aftermarket CPU, or other unneeded components.

The problem is simply an inefficient series regulator design and very

dried-out electrolytic capacitors. There are no cuts needed.

And no RF interference problems either. The information I have provided

is simple to understand, with no irreversible changes.

Update: June 2006

From all the email; the Heathkit GC-1000 Power Supply reliability upgrade

procedure has clearly been an outstanding success.

One expert in the GC-1000 field has been kind enough to share an image

the original GC-1000 program software running in the

Mostek MK3870 MCU. If you are lucky enough to own a piggyback ROM version

of that vintage MCU, you can program a

ROM with the object HEX data in this ZIP

file.

Jeff Thomas

Click

here to return to the Nixie Clock and Nixie Wristwatch site